Back

- Welcome

- About this Report

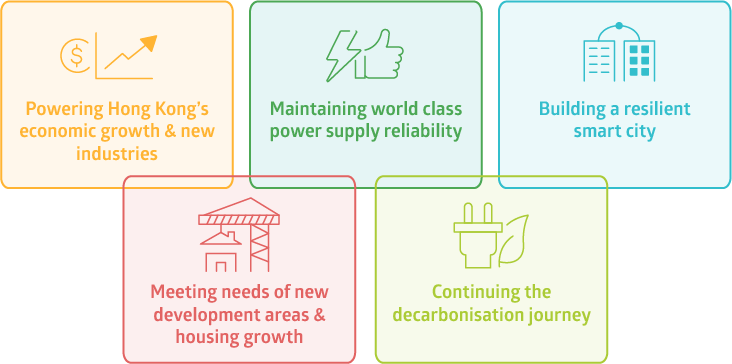

- Approach to Sustainability

- Our Sustainability Agenda

- Respecting Nature

- Serving Our Stakeholders

- Customers

- Our people

- Partners

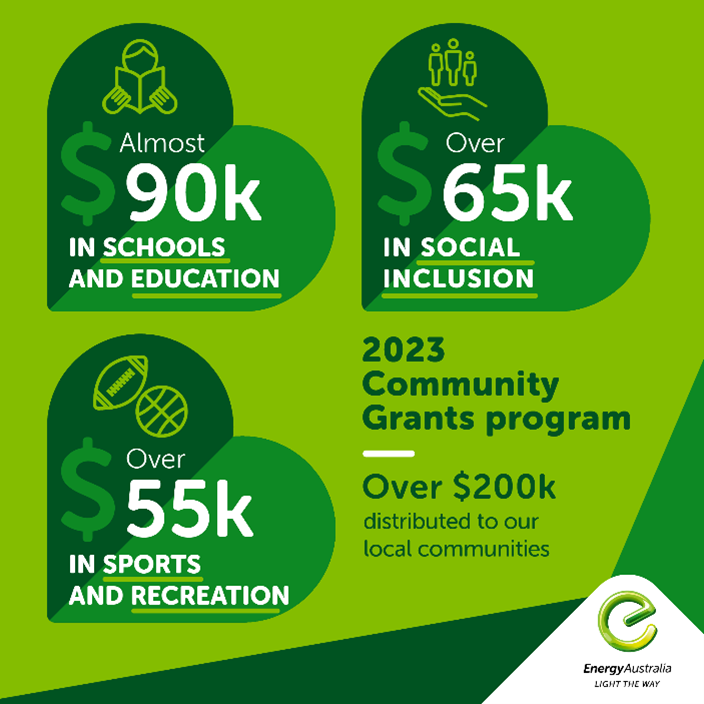

- Community

- ESG Data Table and GHG Accounting Methodology

- Glossary

- Downloads

- Case studies

- Feedback Form

.webp)