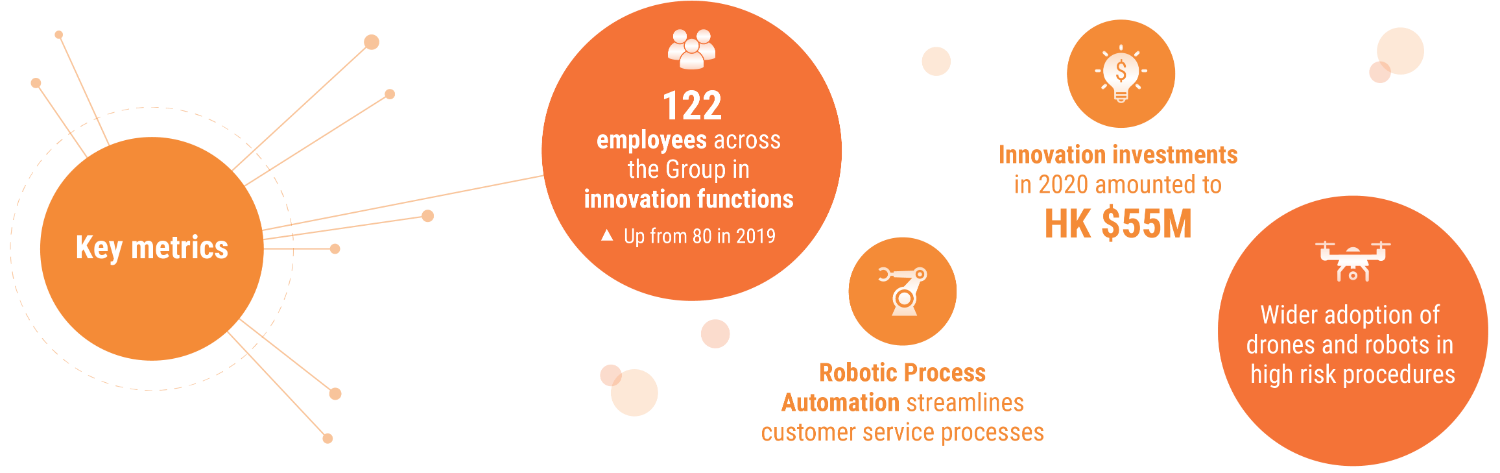

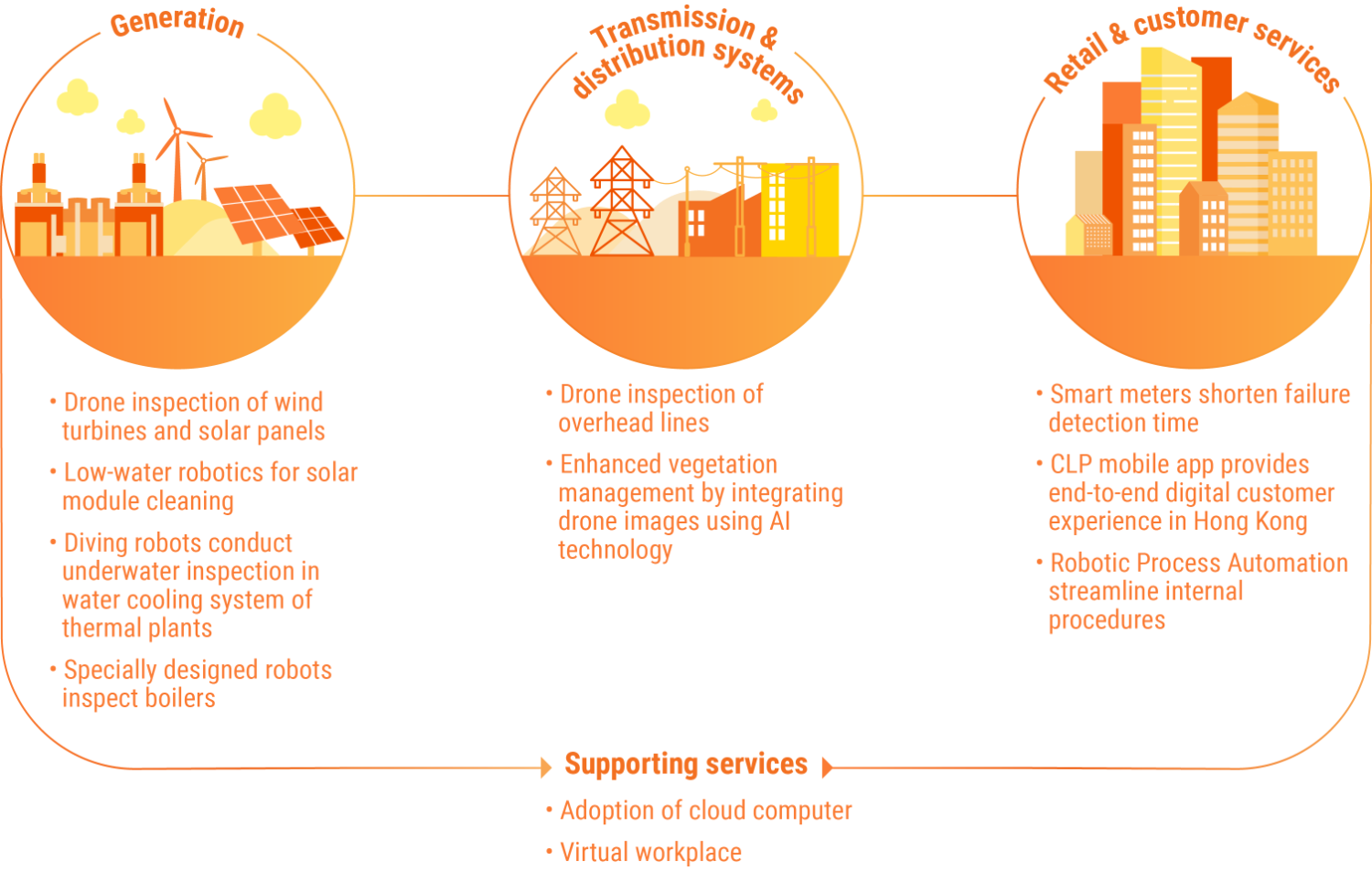

As the onset of the pandemic turned many CLP employees to work-from-home (WFH), CLP’s prior adoption of cloud computing, which commenced in 2018, underpinned business continuity. In 2020, a virtual workplace was rolled out to make remote access more convenient and to facilitate collaboration. This provided CLP with the agility to respond quickly during periods of business disruption by enabling seamless access and updates to IT applications for its employees. The enhanced IT capacity has also had the additional benefit of enabling CLP to hold large scale meetings online, such as the Group’s annual general meeting and CLP Power’s annual Staff Communication Session, where nearly 1,500 employees participated.

Following a review of its IT operating model, CLP is continuing to source more technology services through cloud computing options. This is essential as the Company naturally expands into the big data, machine learning and AI domains.

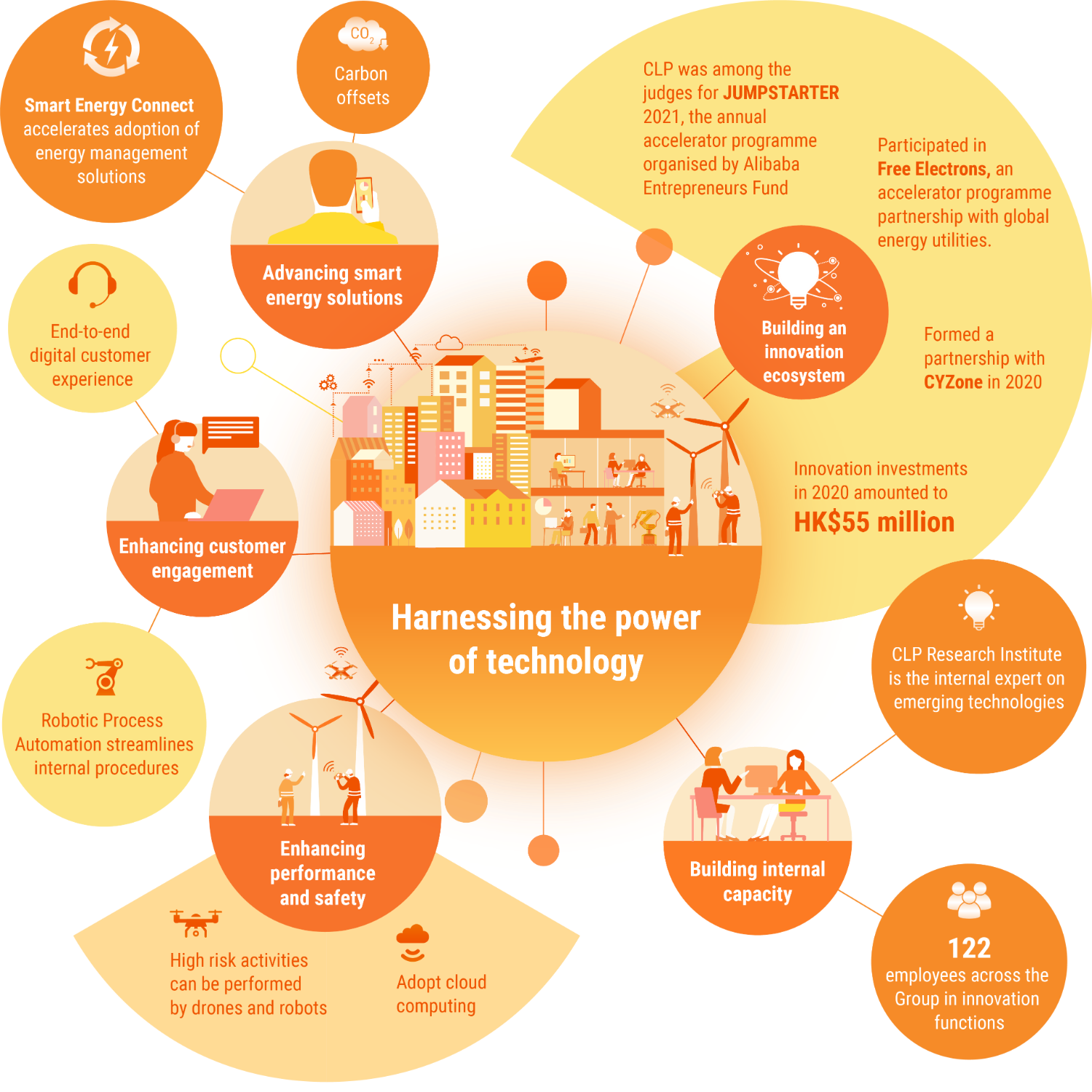

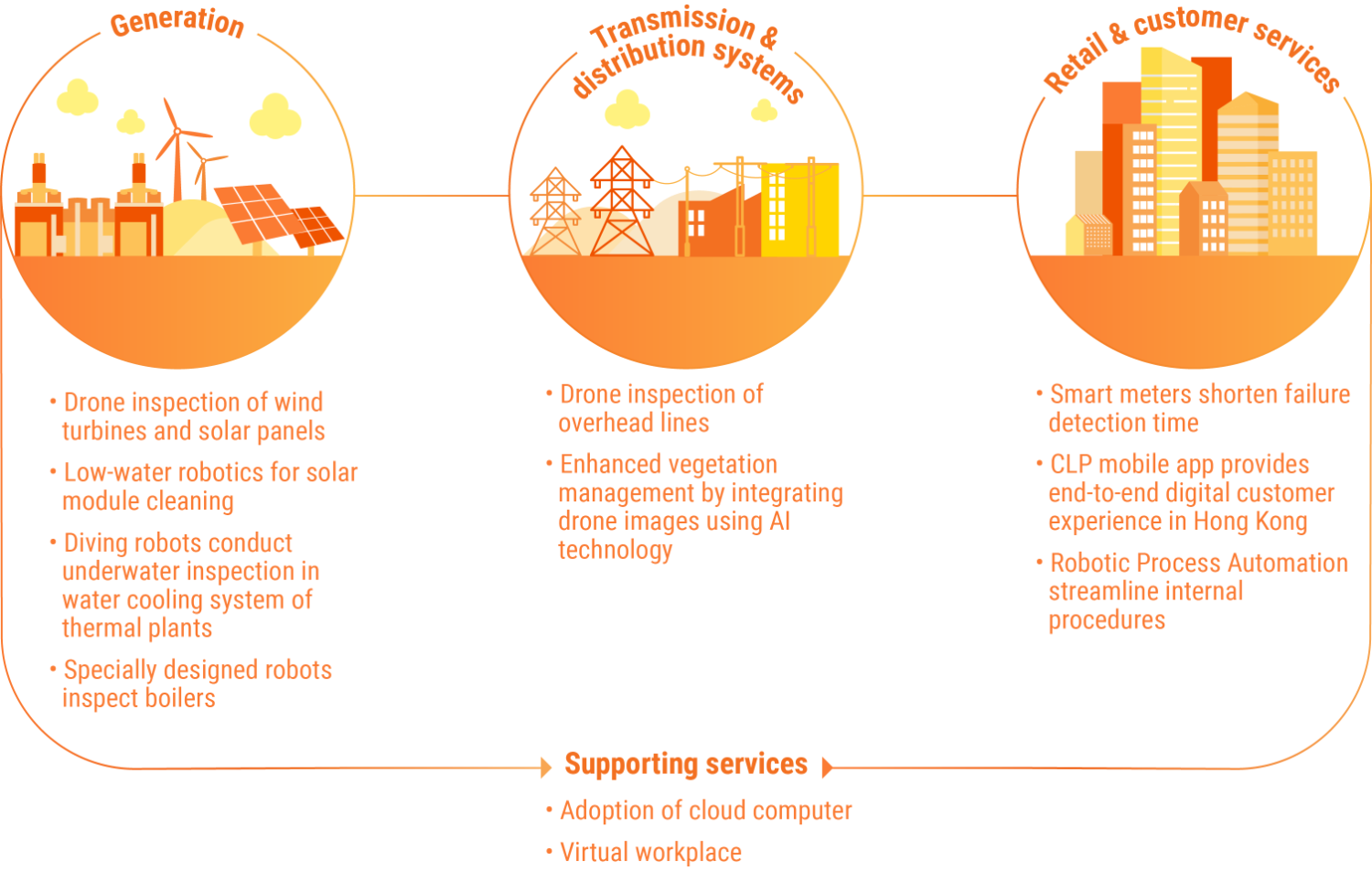

On the operational side of the business, CLP has been expanding deployment of technologies in different activities over the last few years. Unmanned technologies such as drones and robots improve work safety and enhance operational efficiency, especially when they replace humans in challenging and dangerous working conditions – be it underwater equipment used at generation facilities, or for work being conducted on transmission lines 50 metres above ground. It also helps improve power reliability and customer service even though the technology employed may only be visible behind the scene.

For its renewable generation assets, the Company continued to deploy drones for managing its solar assets and for the inspection of wind turbine blades. After a successful trial at the Sihong solar plant in Mainland China, waterless robotics and solar reflectors will be installed in the Huai’an solar farm to improve cleaning procedures and to increase plant efficiency. CLP India has also been trialling the use of low-water robotics for the cleaning of solar modules in Veltoor.

CLP continues to install secondary monitoring and analytics engines across its wind and solar assets in India and China in 2020 and will have full coverage across around 2GW of renewable assets by mid-year 2021. Big data and AI technologies enable remote monitoring and smart network management. The Company has established cloud connections to capture all its renewable data in India and Mainland China, in accordance with data localisation regulations and robust cyber-security solutions to ensure the protection of the operating assets and data.

For the transmission and distribution system, overhead line towers are usually located in remote areas and are prone to damage by nearby vegetation during a typhoon. Using drones, rather than employees, to carry out visual inspections of overhead lines and towers to check their structural integrity and assess the risks posed by any damaged trees nearby is a safer approach. CLP’s engineering team has also been working on the integration of the image data captured by drones using AI technology to enhance vegetation management. The AI algorithms make tree classification easier. By analysing such information together with power asset locations, CLP has established a vegetation management inventory, which allows the Company to identify hazardous trees near power lines, as well as monitor and mitigate the related risks.

The CLP engineering team aims to expand the deployment of these technologies in more aspects of its operations, and has been working with universities to develop new applications for robots and drones. The advanced research and development capability of academics and the practical industrial expertise of CLP engineers are creating synergies to ensure the safety and reliability of CLP’s electricity services.

Beyond its own operations, CLP will focus on the benefits of adopting digital technologies in managing its supply chain, especially data analytics for improved insights into suppliers’ performance and supply chain management. Digitalisation will help deepen CLP’s collaboration with strategic suppliers, enhancing the Group’s access to resources and capabilities in support of business objectives.

Using robots to eliminate high risk diving activities

For thermal assets, the cooling water system and boilers need to be inspected regularly. The use of robots prevents technicians from being exposed to high risk environments.

A combustion boiler is a key component of a thermal asset, which produces steam at high pressure to drive the turbo-generator. A combustion boiler is about 70 metres tall, equivalent to a 22-storey building, and its interior is a confined environment where regular human access is difficult. CLP is now using robots for inspection of some of its boilers. These robots are specially designed to adapt to the conditions of different boilers: some are like spiders that climb on vertical boiler tubes, others have wheels that can navigate the varied terrain. These robots can quickly detect any faults such as surface cracks, significantly reducing the time needed for inspections while improving work safety.

Robots are specially designed to adapt to the conditions of different boilers.

Cooling water culverts, the underwater structures that supply sea water to power generation units for cooling, are another key component that requires regular inspection and cleaning. Traditionally this was done through diving, which is a potentially high-risk activity. CLP took the initiative to use Remotely Operated Vehicles (ROVs) to replace divers for the inspection and cleaning of cooling water facilities in power plants in Hong Kong, Mainland China and Australia. The adoption of ROVs has already eliminated about 30 manned diving hours each year across the Group, in addition to shortening inspection time and reducing asset downtime.

ROVs deploy advanced technology including LED strobe lighting, imaging, underwater GPS positioning, altimeter and echosounder. CLP has worked with consultants and the Hong Kong University of Science and Technology (HKUST) to fine-tune the configurations of ROVs for application at power plants by considering water current, visibility, marine growth and complexity of works. Risk assessments were also conducted to ensure the safe use of ROVs.

Plans are now in place to further reduce or eliminate various manned diving for inspection, cleaning, maintenance, repairs and equipment installation of CLP’s marine works projects, floating solar projects, hydro plants and thermal plants by advancing ROV design changes and operational practice in the coming two years. This effectively minimises the deployment of manpower into highly hazardous underwater environments.

The inspection of underwater cooling water culverts was traditionally done by professional divers.

ROVs are used for inspecting the cooling water inlet tower in the Mount Piper thermal plant in Australia.